Ted Lewis knew the plutonium plates at the government lab where he worked could leak potentially lethal radioactive dust.

Ted Lewis knew the plutonium plates at the government lab where he worked could leak potentially lethal radioactive dust.

He had seen it occur in the 1970s, when he was helping load some of those plates into a nuclear reactor at the lab near Idaho Falls, Idaho. A steel jacket enclosing one of the plates somehow cracked, spilling plutonium oxide particles into the air. But Lewis and his colleagues were lucky – they were wearing respirators and given cleansing showers, so their lives weren’t endangered.

Three decades later, Lewis, an electrical engineer who had become chairman of the lab’s safety committee, had a bad feeling this could happen again, with a worse outcome. And he turned out to be right.

He tried to head it off. In 2009, Lewis wrote a pointed warning memo — he called it a White Paper — and gave it to the official in charge of all nuclear operations at the Idaho National Laboratory, which is run by a consortium of private companies and universities under contract to the Energy Department.

The memo said the chance of encountering a plutonium plate that disintegrated, as Lewis had previously witnessed, was “greater than facility and senior management realizes,” according to a copy. Although Lewis said that a workplace manual published by the contractor – Battelle Energy Alliance, LLC (BEA)* — called the risk of an accidental spill of such radioactive dust “negligible,” he wanted his superiors to expect it and prepare for it.

He said in a sworn court deposition in January 2016 that he shared his concerns with at least 19 others at the laboratory, which holds one of the world’s largest stockpiles of plutonium, the explosive at the heart of modern nuclear weapons. But they didn’t respond, he said, and some of the precautions he urged — checking the plates more carefully before they were unwrapped and repackaged for shipment and setting up a decontamination shower — were ignored.

Then, at 11:04 a.m. on Tuesday, Nov. 8, 2011, Lewis’s fears came to life in a cavernous room at the lab where workers were readying some plates the size of Hershey’s chocolate bars for shipment to other federal sites and to researchers. The workers had a lead shield between themselves and the plates, but the table where they sorted the plates wasn’t sealed, and none of them had respirators on.

So when a nuclear material handler named Ralph Stanton noticed that one of the plates had a label warning that its corner was “swollen,” he asked a shift supervisor for guidance. The supervisor phoned one of the lab officials whom Ted Lewis had briefed on his worries, but after finishing the call the official told the workers to continue, according to an internal Department of Energy report in January 2012.

Sure enough, as the plastic wrapping was cut, black powder leaked out, and Stanton, along with 15 of his colleagues in the facility, inhaled the plutonium dust, according to the report. Three of them wound up suing BEA, saying that they had been sickened due to the company’s negligence. BEA publicly disputed that the workers were harmed, but it also reached private settlements with each of the litigants that included nondisclosure provisions.

The contamination incident was extensively covered by two newspapers published in Boise, the Idaho capital. But the Center for Public Integrity’s investigation shows it was preceded by two other serious instances of radioactive contamination at the lab as well as by Lewis’s careful warnings, and that it was also followed by two additional, avoidable radioactive contaminations there.

Laboratory deputy director Juan Alvarez said in an emailed statement that the lab’s leaders took the inhalation incident seriously and agreed with the Energy Department’s conclusion that “the accident was preventable.” As a result, he said, “the facility was closed for nine months and 80 corrective actions were implanted.” He and spokeswoman Sarah Neumann did not answer other questions about specific safety incidents but Alvarez added that “we value our people” and “learn from the past.”

Accidents persisted at the lab after the 2011 incident. But officials in Washington charged with overseeing worker safety — and annually deciding how much profit BEA would be paid based on its performance — decided not to let the incidents seriously dent the company’s revenues.

They failed, in short, to use either of two key federal levers available to force improved workplace protections for those involved in handling the nuclear materials that underpin America’s security — by imposing fines or cutting profits enough to compel an end to new safety hazards, or by holding up or completely blocking an extension of the lab’s private management contract.

During the period of the five worker radiation contaminations from 2011 to 2014, the Energy Department paid BEA $68.5 million in pure profits, amounting to 92 percent of the maximum its contract allowed, the Center’s tally shows. (Its actual expenses in running the lab were reimbursed in full.)

The fines and profit cuts levied against the consortium for the five safety incidents — including $500,000 for the November 2011 incident — amounted to less than one percent of this total. And a year later, the Energy Department gave BEA the $500,000 fine back, after concluding it had made needed corrective actions.

Moreover, in 2014 — the year that two new contamination episodes occurred — the contractor group received a five-year extension of its contract without a competition urged by federal regulations, enabling it to forgo millions of dollars in costs associated with a new contest.

That’s not all. BEA’s contract with Washington — like those the government has signed with most nuclear weapons-related contractors — allows it to pass along to taxpayers the costs of resolving safety-related litigation by its workers, except in the event of what government officials conclude is gross negligence, discrimination, or improper retaliation against whistleblowing.

BEA has asserted that those exceptions didn’t apply in the 2011 plutonium exposure, and so it has asked the government to pay the secret sums it had to spend to squelch the lawsuits by workers Stanton, Brian Simmons and Steve Braase, according to Lindsey Geisler, an Energy Department spokeswoman. Geisler said the Energy Department is still reviewing that request.

Generally, the government has said “yes” when it’s been asked to reimburse these contractors for litigation costs, and mostly in a slapdash manner, according to a Feb. 2016 report by the Energy Department’s inspector general. After reviewing reimbursements to contractors totaling $62 million between 2009 and 2011 involving 46 legal settlements, some of which involved whistleblower complaints, allegations of discrimination and other accusations, acting Inspector General Rickey Hass concluded that the department had properly screened only about a fifth to see whether the exceptions applied.

Even when the contractors do wind up paying fines, the amounts are too small to pose much of a deterrent, or wind up being treated as routine, acceptable business expenses, experts say.

“The mere fact that they continued to have the same kinds of incidents tells you these penalties do not function as a deterrent,” said Celeste Monforton, a former Occupational Safety and Health Administration policy analyst who lectures on workplace safety at Texas State University. She called the fines assessed against BEA, amounting to just a few percent of its federally-paid profits, “insignificant . . . There’s nothing about these penalties that are painful. I don’t even want to call this the cost of doing business, because it’s not costly.”

Monforton added: “It is known and recognized how not to get radiation exposures. The procedures are understood. They should not be able to earn as much profit when they have pressures that create an environment where people are harmed . . . It takes a lot of gall to ask taxpayers to pay for this.”

Idaho National Laboratory is not unique. The government has been similarly generous to many of the other private contractors that operate key nuclear weapons-related facilities. Part of the problem, according to auditors at the Government Accountability Office, which reports to Congress, is that the Energy Department has too little staff, and poorly-trained contract managers, making it more susceptible to fraud and waste than most agencies.

The contractors largely police themselves, according to the GAO and inspector general reports. And — as might be expected — the contractors typically prioritize the mission-related responsibilities that bear directly and most strongly on their profits, according to current and former workers and accident investigation reports.

Plenty of warning that workers were at risk

Lewis’s “white paper” was not the only sign that BEA’s effort to prevent radiation contamination of its Idaho workforce were lagging.

In the final quarter of 2010, two workers were repairing manipulators — robotic arms that are used to remotely handle radioactive materials — in a tall, boxy structure at the Idaho nuclear complex called the Hot Fuels Examination Facility. They were doing the repairs in a sealed glove box, in which workers manipulate radioactive materials through heavy rubber gloves. But the glove box was highly contaminated inside — and leaky — so they received high radiation doses, according to a DOE violation notice of Oct. 4, 2012, and a BEA report dated Oct. 23, 2012.

They didn’t learn about it until three months after their highest exposure, the investigation report said, because the technicians who read and record their exposures didn’t make it a priority to tell them. As a result, one exceeded his annual company-set radiation dosage limit of 10 rem in 2010, and the other worker nearly exceeded his limit.

The reports said workers should have been told along the way of their monthly exposures, so they were not surprised by their cumulative doses. Also, in a problem that would recur in multiple incidents, the lab did not check the glovebox for a particular type of radiation commonly exuded by the material they worked on, according to the BEA investigative report. That type of radiation is not harmless — it can cause cell damage, cancer, and even death in high doses.

Work in the facility was stopped for three months in early 2011 to review procedures and re-train the staff there, but the retraining didn’t seem to take hold.

Later that year, workers tasked with checking radiation levels emitted by small disks of spent nuclear fuel needed elsewhere at the lab ignored radiation readings that registered off-the-scale of their monitors, reasoning that because their work orders did not set limits for that particular type of radiation it wasn’t their concern. “No problems noted during work activities,” a technician wrote, according to a November 2011 analysis of the incident done by the lab for the DOE.

When the disks arrived at their destination, the technicians took readings of their own and reacted with shock. One immediately phoned his colleagues at the hot fuel building to ask, “what [they] had just sent because his meter pegged,” the lab’s report said. He complained to managers, supervisors, technicians and engineers that he had gotten “hot” samples.

The disks were returned so they could be trimmed in size to reduce their radioactivity. But technicians were not warned of the dangers of handling them or told that grinding them down could actually increase their radiation emissions, according to the BEA report. So they were again handled by workers without appropriate shielding.

One showed a radiation exposure of 3.58 rems to his right hand, which was less than the contractor-set exposure limit of 10 rems for the year. But the initial investigation report and BEA’s own analysis said that the lab should have set additional exposure limits and not subjected its employees to radiation needlessly.

Numerous problems contribute to the mass inhalation incident

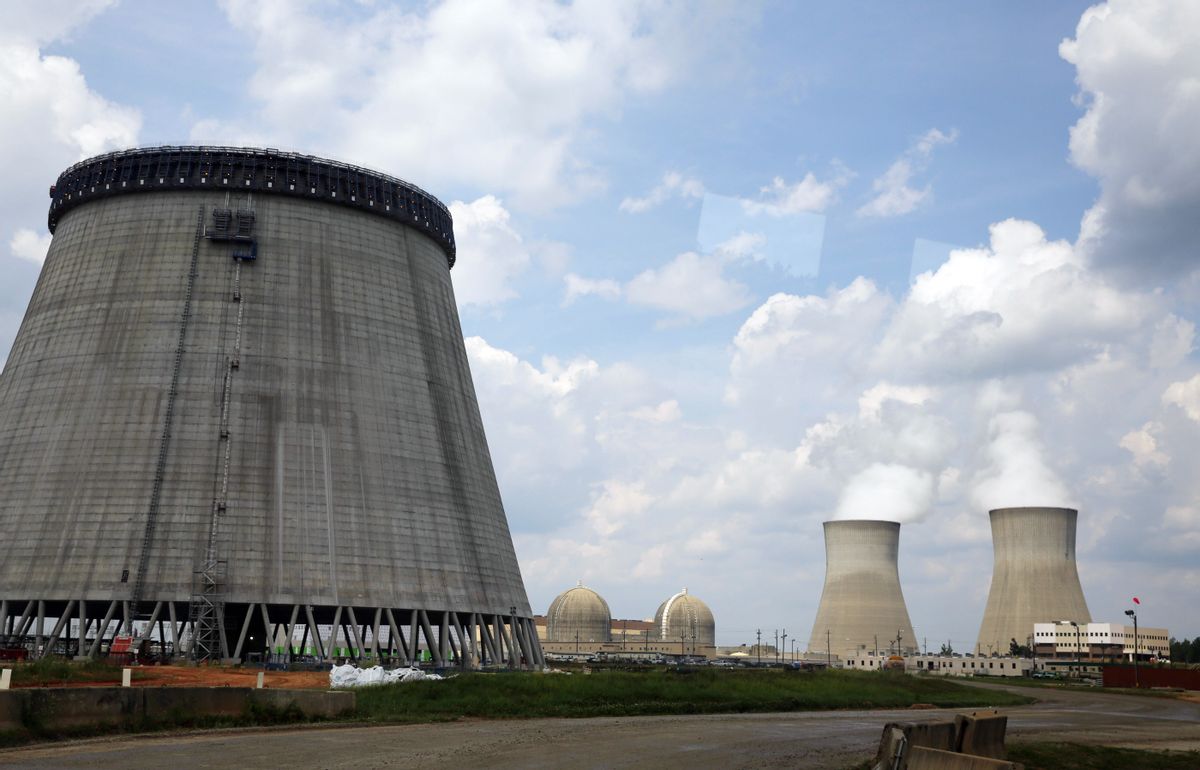

Then came the radiation contamination of 16 workers on Nov. 8, 2011, which occurred in a white, mound-shaped building that was once home to a mothballed nuclear reactor and still has a massive vault resembling a walk-in freezer. It’s there that the government stores several metric tons of surplus plutonium, which the Department of Homeland Security and the NNSA use to help develop and refine radiation detection devices deployed by Washington at ports and border crossings around the globe.

Multiple physical shortcomings and managerial lapses combined to endanger the workers that day, according to the Energy Department’s report: The building had old and failing equipment, and no showers. Records of the plutonium plates’ individual histories – including previous damage -- had been lost, and Lewis’s warnings that some were liable to turning to powder were ignored. Managers “did not recognize the significance of this information,” the report said.

Worse, the nearest air monitor was 15 feet from where the plates were being unwrapped. A vent supposed to draw dangerous fumes from the work area was partially blocked. And some of those doing the work “had no training on the hazards associated with Pu [plutonium],” BEA’s report said.

According to the lawsuits filed against BEA, the company at the time felt compelled to complete the work speedily. In interviews with the Center, Stanton said he was told it was a “bonus job,” meaning that meeting deadlines would help the company and its managers earn their profits. “DOE gives these guys a bonus. When the milestone is in play, safety is completely gone,” he said. “We were playing Russian roulette.”

Braase, a health physicist technician responsible for checking jobsite radiation and worker exposures, said in his own legal complaint that the work was accelerated so it could be completed before he went on a medical leave, allowing less time than usual for a careful review. BEA’s report on the accident, issued Sept. 17, 2012, said that one of the factors contributing to the accident was that the company’s “focus is on getting the work done (the end justifies the means).”

According to the reports and the accounts obtained by the Center from those present, when the powder spilled out, Braase, the health physicist, pointed a radiation meter at a portion of it from three inches away, and the needle leapt into the red. Three minutes after the spill, the alarm across the room screamed.

Stanton, Simmons, Braase and the other workers in the room fled to the building’s control room, where they watched a radiation meter in their workplace swiftly climb to a level hundreds of times above a trigger for donning respirators. “I was scared. Everybody was,” Stanton said. “We knew this was bad.”

A hand-held monitor showed that Braase had plutonium on his face, hair and body, he said in his lawsuit. His clothing was removed, and workers used towels and wipes to clean his skin before putting him into a shower in another building. Those with the highest levels of contamination, including Stanton and Simmons, were shuttled to a building 20 miles away, where they were given intravenous medicine to counter the effects of the radiation.

But the building where they were exposed had no showers at all, and a second building they were taken to had no hot water, the DOE’s final report said. Only Braase and one other worker received showers.

One week after the incident, on Nov. 15, BEA’s health and safety director Sharon Dossett dismissed its significance during a meeting of the Idaho National Laboratory Environmental Management Citizens Advisory Board, which includes prominent civic leaders among its members. Asked about the effect of the doses on the employees, Dossett replied “that the dose was low enough that it would not prevent the workers from doing radiological work,” according to the minutes of the meeting.

The gravity of their exposures has nonetheless been contested, partly because the urine samples the workers provided on the day of their exposure were altered by the medication that four of them, including Braase, Simmons and Stanton, were swiftly given. In his lawsuit, Simmons said BEA radiation control officials initially showed him a report saying that his bone surface dose could have been as high as 265 rem, a level five times the annual federal occupational dose limit, 212 times the Occupational Safety and Health Administration limit, and 2,650 times the annual federal dose limit for the public.

He was not allowed to keep the memo, Simmons said, but Stanton, who was with him, said he saw it too. Stanton recalls that it was shown to them by Dave Georgeson, BEA’s lead dosimetrist, and Laurie Kornacki, an internal dosimetry manager, on Dec. 14, 2011, five weeks after the accident.

There is some uncertainty about that estimate, however, because the underlying assumptions behind it were not made clear to the two men. Simmons said in his lawsuit that he saw a separate calculation by Oak Ridge National Laboratory around the same time that his most probable dose was 70.6 rem to the bone surface, a level he called “well over the 50 rem federal annual limit for occupational exposure.” Braase, in his lawsuit, claimed his urine samples showed his dosage was 23.8 rem to the bone surface. Stanton, now 52, said his own exposure was lower, but it was still high enough for the company to bar him from returning to work for eight months.

DOE’s final report, however, expressed the dose estimates in less certain terms. It said only that two workers had “the potential of exceeding the 50 rem annual limit to an individual organ/tissue.” Braase claimed he was one of them.

Health physicists consulted by the Center noted that the unusual circumstances complicate estimates of the potential consequences. If you inhale plutonium particles, they sit in the lung or get into the bloodstream and continue to radiate for a lifetime or until they are all are excreted. As a result, labs generally predict exposures and assign limits for this type of exposure over a 50-year period. Annual radiation limits for workers, for the most part, are pegged to short-term exposures from sources outside the body — like from an x-ray or series of x-rays.

When Simmons claimed in his lawsuit that his exposure was 70.6 rem to the bone surface, he was using a number which estimates his accumulated bone dose over 50 years, according to Ronald Kathren, president of the Health Physics Society from 1989 to 1990 and a professor emeritus of health physics at Washington State University. He said that even though the 70.6 rem number sounds high, it represents 50 years’ worth of exposure. “The risk would be very small from getting bone cancer from this dose,” he said.

Even Simmons’ claimed exposure of 265 rem would not be worrisome if it were an estimate of exposure to the bone over 50 years, Kathren said. But he added that “if a guy had gotten 250 rem in the first year, I would be very concerned.”

Uncertainty about exactly how — or when — the inhalation of plutonium might affect his health haunts Stanton. “I’m always worried this will be what comes back and gets me,” he said.

Stanton and Simmons also say they encountered public hostility from some of their colleagues after they pressed managers and health officials from the company for details of their contamination levels and lax workplace safety practices. “Brian and I sat alone at lunch,” Stanton recalled. “We were total outcasts. But when we were alone and saw them in the hall, people that wouldn’t acknowledge you around management thanked us.”

Eleven months after the mishap, on Oct. 4, 2012, Idaho National Laboratory finally called a press conference to discuss the accident, where Dossett announced that the exposures of all 16 employees were below the 5 rem annual exposure limit for the whole body, a level set by federal standards. "This is the level all industrial workers are allowed to be exposed to," Dossett said.

Dossett’s claim was based on a recalculation of the dosages by radiation health experts at an Energy Department laboratory located at Oak Ridge, Tennessee. In an email on Oct 23, 2012, a manager at BEA’s radiation control team thanked seven experts at the lab for their work overriding the higher, preliminary estimates.

The Oak Ridge study was “critical to RadCon being able to reduce personnel doses by at least 50% and in many cases even more,” the message said, according to a copy obtained by the Center. “Without the work you performed, INL employees might have been assigned much greater doses and as a result, BEA could have been facing steeper . . . penalties,” it said.

In the end, the Energy Department’s enforcement director, John S. Boulden III, avoided reaching a clear conclusion, opting instead for a declaration that the exposure had “a high potential for an adverse impact on worker safety,” according to an Oct. 2012 enforcement letter he wrote to the Idaho National Laboratory Director John Grossenbacher.

Lewis, the author of the disregarded warning letter, said in his deposition that as the lawsuits were being filed against BEA in 2014 and 2015, Jeff Riedesel, the company’s deputy head of nuclear operations, called him out of the blue “and asked me if I had anything to change or add” to the text of the warning he had given. “I said, no, I’m not changing or adding anything, that what you have is what I put down, and that’s what I’ve said,” Lewis said in his deposition.

He said that while the company’s leaders never intended to harm workers, “I feel that there were opportunities missed” to protect them. Multiple messages left for Riedesel by phone, email and social media went unreturned. BEA spokeswoman Neumann declined to comment when asked about the call Lewis described in his deposition.

In an interview with the Boise Weekly, Grossenbacher, director of the lab and president of BEA, acknowledged the lab’s “complacency” when it came to risks posed by the old plutonium plates. “I don’t think we paid enough respect to that uncertainty and the hazard,” he said.

For this incident, and for the earlier radiation exposures that year of the three workers in the hot fuel facility, the DOE’s enforcement officer initially proposed fining BEA $615,000 but Bouldon reduced the fine to $412,500 for what he said were “corrective actions taken.”

Separately, BEA’s profit was cut by $500,000 on Jan. 31, 2012, in a letter from Richard B. Provencher, the DOE’s fee awarding official, to Grossenbacher that noted “unacceptable events continue to occur” at the lab. But on Nov. 22, 2013, Provencher, who determines BEA’s annual profit, gave back the entire $500,000 that had been withheld, with the stipulation that BEA spend $100,000 of it on efforts to improve operations and safety.

In total, in 2011, BEA earned $17.1 million in profits, the year of the accident, or 92 percent of what was available. In 2012, it earned $16.2 million, but the next year it got the $500,000 back.

New contamination incidents

The plutonium contamination of 16 BEA workers was followed by two other significant radiation exposures, with the first occurring in August 2014, when workers in the Fuel Manufacturing Facility, a low structure next to the building where the plutonium exposures occurred, were fabricating radioactive americium in a glove box.

Outside the body, small bits of americium pose almost no threat to human health. But in higher internal doses, its radiation breaks down cells, alters genes and attacks bones and organs, increasing its victims’ chances of contracting life-threatening maladies, according to the Centers for Disease Control and Prevention.

Air monitor alarms in the work room sounded four times during the glove box work, but because no one found any contamination on the room’s surfaces, it was assumed americium was not in the air. A month later, however, the lab discovered americium-241 in the air filters that had been in place during the August work.

For reasons that remain unclear, investigators were unable to find the source of the contamination for the next 16 months. But eventually they discovered that the glove box the workers used, which should have been sealed tight, had leaks in seven places. Nine workers were tested and found to have inhaled doses of less than 100 millirem of americium-241, according to a DOE enforcement letter of August 2016.

The letter said that the safety consequences of the event were low, but called the incident “preventable” and said “DOE views seriously any event in which workers received unplanned radiological uptakes.” The letter, signed by enforcement director Steven Simonson, imposed no safety fines or penalties.

The fifth contamination incident occurred just two weeks later, in a long, low building just a block from the Idaho fuel manufacturing facility known as the Analytical Laboratory. There, on Sept. 9, 2014, a researcher poured some nitric acid containing plutonium-238 into another bottle, all inside a small room with a special exhaust fan. A week later, routine monitoring detected plutonium contamination in the room. Those involved had their noses swabbed, and two workers had nasal contamination, but no plutonium was detected in their lungs. The room was then shut for a week for decontamination.

An initial investigation report by the contractor said the researcher did not follow procedures to decide whether the work should have been done in a sealed glove box. “Emphasis on schedule exceeded emphasis on methods/doing a good job,” said the Oct. 29, 2014 report, striking a chord that appears in many of the DOE reports on radioactive contaminations throughout the country’s nuclear weapons complex.

The incident, however, did not provoke a specific enforcement action, and again, DOE did not levy any fines — another familiar outcome.

At the end of 2014, BEA was awarded $18.1 million in pure profit, after $350,000 was deducted for the two safety incidents and other issues. That meant the company got 97 percent of the maximum profit allowed under its contract. It also got its contract extended to 2019 without competition. A joint news release from BEA and the Energy Department announcing the extension credited the decision to the company’s “consistently strong annual performance and success in managing INL.”

*. BEA is a consortium consisting of Battelle, private non-profit based in Ohio, and BWX Technologies, AECOM, Electric Power Research Institute, and an alliance of eight universities.

Shares